CC-XD “Xtreme Duty” Elevator Bucket

High Density Polyethylene

Our extra-strength bucket was built to hold up under the most rigorous of conditions. The extra thick walls and reinforced lip create a stronger and tougher CC-style bucket, while its higher ears and flat bottom breaks give it a greater capacity. Because it is thicker and heavier weight than a regular CC-style bucket, it may require a stronger belt and higher horsepower.

Why Polyethylene?

This material is non-corrosive, tough and flexible, so polyethylene buckets create less product damage, reduce backlegging, and are nonsparking. It is lightweight and has a clean discharge, which makes polyethylene perfect for free-flowing product applications.

Features

- Prime virgin, high-density polyethylene

- Available in 24 sizes

- Capacity is 5% above water level

- Spacing is 1” less than nominal projection

- Requires sufficient belt strength and horsepower

Applications

- Grains

- Feeds

- Fertilizers

- Seeds

- Salt

- Sand

- Chemicals

- Food Products

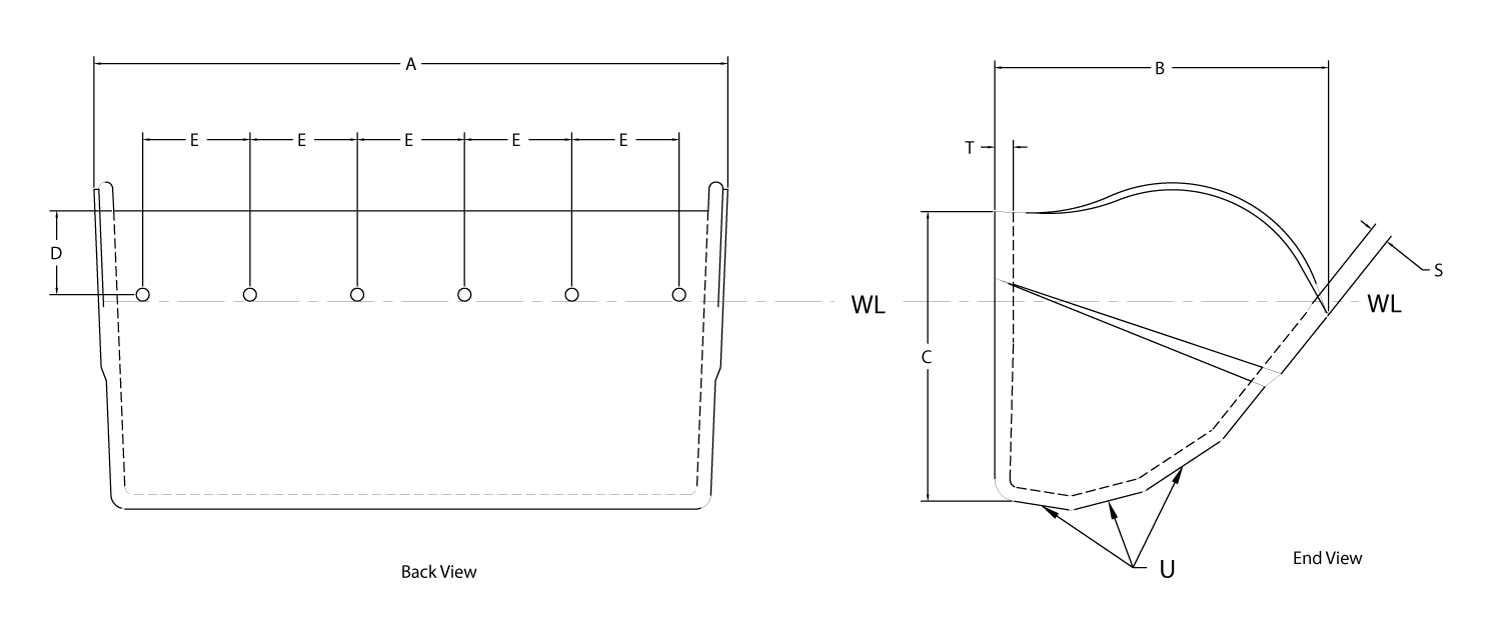

Measurement Conversion: Imperial

CC-XD "Xtreme Duty" Elevator Bucket

| Size (Nominal) Inches |

Dimension-Actual (Inches) Tolerance A, B, C ± 3/16" T± 1/32" |

Drilling-Standard (Inches) ✝ Tolerance E ± 1/32", D ± 1/4" |

Capacity ■ Tolerance ± 3% | Spacing on Belt (Min.) Inches | Weight (Pounds) | Number Per Carton | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Proj. B | Depth C | Thickness T | Thickness S | From Top D | Center to Center E |

# of Holes | Bolt Diameter | WL | WL + 10% | Each (Avg.) | Per Carton (Avg.) | |||||

| Cu. In. | Cu. Ft. | Cu. In. | Cu. Ft. | ||||||||||||||

| 6 X 5 | 6-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 4-3/8 | 2 | 1/4 | 73.80 | 0.043 | 81.18 | 0.047 | 5-1/2 | 1.14 | 27.4 | 24 |

| 7 X 5 | 7-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 2-11/16 | 3 | 1/4 | 86.40 | 0.050 | 95.04 | 0.055 | 5-1/2 | 1.30 | 31.2 | 24 |

| 8 X 5 | 8-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 3-1/16 | 3 | 1/4 | 98.40 | 0.057 | 108.24 | 0.063 | 5-1/2 | 1.38 | 33.1 | 24 |

| 9 X 5 | 9-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 3-5/8 | 3 | 1/4 | 111.1 | 0.064 | 122.21 | 0.071 | 5-1/2 | 1.47 | 44.1 | 30 |

| 10 X 5 | 10-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 4-1/8 | 3 | 1/4 | 121.10 | 0.070 | 133.21 | 0.077 | 5-1/2 | 1.58 | 19.0 | 12 |

| 11 X 5 | 11-11/16 | 5-11/16 | 5-11/16 | 5/16 | 3/8 | 1-1/2 | 3 | 4 | 1/4 | 137.3 | 0.079 | 151.03 | 0.088 | 5-1/2 | 1.71 | 51.3 | 30 |

| 8 X 6 | 8-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 3-1/16 | 3 | 1/4 | 138.50 | 0.080 | 152.35 | 0.088 | 6-1/2 | 2.03 | 48.7 | 24 |

| 9 X 6 | 9-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 3-5/8 | 3 | 1/4 | 155.60 | 0.090 | 171.16 | 0.099 | 6-1/2 | 2.16 | 51.8 | 24 |

| 10 X 6 | 10-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 4-1/8 | 3 | 1/4 | 175.40 | 0.102 | 192.94 | 0.112 | 6-1/2 | 2.33 | 23.3 | 10 |

| 11 X 6 | 11-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 3 | 4 | 1/4 | 190.70 | 0.111 | 209.77 | 0.122 | 6-1/2 | 2.46 | 24.6 | 10 |

| 12 X 6 | 12-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 3-3/8 | 4 | 1/4 | 205.00 | 0.119 | 225.50 | 0.131 | 6-1/2 | 2.58 | 25.8 | 10 |

| 13 X 6 | 13-11/16 | 6-13/16 | 6-3/4 | 11/32 | 7/16 | 1-3/4 | 3-5/8 | 4 | 1/4 | 222.70 | 0.129 | 244.97 | 0.142 | 6-1/2 | 2.82 | 25.4 | 9 |

| 11 X 7 | 11-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 3 | 4 | 5/16 | 252.30 | 0.146 | 277.53 | 0.161 | 7-1/2 | 3.49 | 27.9 | 8 |

| 12 X 7 | 12-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 3-3/8 | 4 | 5/16 | 273.40 | .0159 | 300.74 | 0.174 | 7-1/2 | 3.64 | 29.1 | 8 |

| 13 X 7 | 13-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 3-5/8 | 4 | 5/16 | 303.00 | 0.176 | 333.30 | 0.193 | 7-1/2 | 3.95 | 31.6 | 8 |

| 14 X 7 | 14-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 3 | 5 | 5/16 | 322.50 | 0.187 | 354.75 | 0.206 | 7-1/2 | 4.13 | 33.0 | 8 |

| 15 X 7 | 15-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 3-1/4 | 5 | 5/16 | 350.60 | 0.203 | 385.66 | 0.224 | 7-1/2 | 4.21 | 33.7 | 8 |

| 16 X 7 | 16-11/16 | 7-15/16 | 7-7/8 | 3/8 | 1/2 | 2 | 2-7/8 | 6 | 5/16 | 376.20 | 0.218 | 413.82 | 0.240 | 7-1/2 | 4.47 | 35.8 | 8 |

| 12 X 8 | 12-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 2-1/4 | 3-3/8 | 4 | 5/16 | 365.50 | 0.212 | 402.05 | 0.233 | 8-1/2 | 4.73 | 37.8 | 8 |

| 14 X 8 | 14-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 2-1/4 | 3 | 5 | 5/16 | 420.20 | 0.244 | 462.22 | 0.268 | 8-1/2 | 5.18 | 41.4 | 8 |

| 16 X 8 | 16-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 2-1/4 | 2-7/8 | 6 | 5/16 | 483.60 | 0.280 | 531.96 | 0.309 | 8-1/2 | 5.76 | 46.1 | 8 |

| 18 X 8 | 18-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 2-1/4 | 3-1/8 | 6 | 5/16 | 563.00 | 0.327 | 619.30 | 0.359 | 8-1/2 | 6.38 | 51.0 | 8 |

| 20 X 8 Patented | 20-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 1-1/4 | 3-1/2 | 6 | 5/16 | 609.00 | 0.353 | 669.90 | 0.389 | 7 | 7.28 | 58.2 | 8 |

| 22 X 8 | 22-11/16 | 9-1/16 | 8-15/16 | 1/2 | 1/2 | 2-1/4 | 4 | 6 | 5/16 | 687.70 | 0.399 | 756.47 | 0.439 | 8-1/2 | 7.76 | 62.1 | 8 |

| 12 X 9 | 12-11/16 | 10-3/16 | 10-1/16 | 9/15 | 9/16 | 2-1/2 | 3-3/8 | 4 | 5/16 | 457.68 | 0.265 | 503.45 | 0.292 | 9-1/2 | 5.99 | 35.9 | 6 |

| 14 X 9 | 14-11/16 | 10-3/16 | 10-1/16 | 9/16 | 9/16 | 2-1/2 | 3 | 5 | 5/16 | 537.00 | 0.311 | 590.70 | 0.343 | 9-1/2 | 7.38 | 44.3 | 6 |

| 16 X 9 | 16-11/16 | 10-3/16 | 10-1/16 | 9/16 | 9/16 | 2-1/2 | 2-7/8 | 6 | 5/16 | 616.70 | 0.358 | 678.37 | 0.393 | 9-1/2 | 8.37 | 50.2 | 6 |

| 18 X 9 | 18-11/16 | 10-3/16 | 10-1/16 | 9-16 | 9/16 | 2-1/2 | 3-1/8 | 6 | 5/16 | 692.62 | 0.401 | 761.88 | 0.442 | 9-1/2 | 8.04 | 48.2 | 6 |

| 20 X 9 | 20-11/16 | 10-3/16 | 10-1/16 | 9/16 | 9/16 | 2-1/2 | 3-1/2 | 6 | 5/16 | 779.00 | 0.452 | 856.90 | 0.497 | 9-1/2 | 9.66 | 58.0 | 6 |

| 14 X 10 Patented | 14-11/16 | 11-5/16 | 11-1/8 | 5/8 | 5/8 | 1-3/4 | 3 | 5 | 3/8 | 650.21 | 0.376 | 715.23 | 0.415 | 9 | 8.56 | 51.4 | 6 |

| 16 X 10 | 16-11/16 | 11-5/16 | 11-1/8 | 5/8 | 5/8 | 2-3/4 | 2-7/8 | 6 | 3/8 | 750.60 | 0.435 | 825.66 | 0.479 | 10-1/2 | 9.53 | 57.2 | 6 |

| 18 X 10 Patented | 18-11/16 | 11-5/16 | 11-1/8 | 5/8 | 5/8 | 1-3/4 | 3-1/8 | 6 | 3/8 | 850.37 | 0.492 | 935.41 | 0.543 | 9 | 10.24 | 61.4 | 6 |

| 20 X 10 | 20-11/16 | 11-5/16 | 11-1/8 | 5/8 | 5/8 | 2-3/4 | 3-1/2 | 6 | 3/8 | 965.10 | 0.560 | 1061.610 | 0.616 | 10-1/2 | 11.60 | 69.6 | 6 |

| 24 X 10 Patented | 24-11/16 | 11-5/16 | 8-3/4 | 5/8 | 5/8 | 1-3/4 | 3-1/2 | 7 | 3/8 | 1115.82 | 0.646 | 1227.402 | 0.712 | 9 | 12.50 | 75.0 | 6 |

■ Tapco recommends using the WL (water level) fill capacities shown in table above. A gross capacity figure is no longer provided as it is inappropriate for rating an agricultural elevator bucket

Standard bolt holes drilled on the WL (Water Level) line ± 1/4"

Note: All sizes of 8", 9" and 10" projection buckets can be modified to CCLP style for closer spacing

Style:

CC-XD (Xtreme Duty)

Design:

High speed centrifugal discharge.

Method of Manufacture:

Injection molded.

Color:

Blue. White available upon request.

Temperature Range:

-60°F to + 200°F/-51°C to + 93°C.

Flammability:

The high density polyethylene used in Tapco buckets is termed “slow burning”. It has been tested under ASTM Test No. D635. It also meets the criteria for approval under the Motor Vehicle Safety Standard No. 302 and Underwriters’ Laboratory Bulletin No. 94. Combustion in an excess of air results in harmless by-products (fumes) which are nontoxic.

Standard Drilling:

No Charge.

Special Drilling:

Any pattern and hole diameter can be provided at minimal cost.

Venting:

Available in five standard patterns. See catalog for specifications. Venting page.

Usable Capacity:

Net or usable capacity could range from 10% to 20% above water level. For engineering purposes Tapco recommends using WL (Water Level) + 10% for usable capacity.

Spacing:

Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes Tapco recommends using nominal projection plus 2".

Interchangeability:

Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. CC-XD buckets have a greater projection than CC-HD buckets. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Fanged elevator bolts and nylon insert lock nuts are recommended. Flat steel washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

FDA Status:

Polyethylene used meets the requirements of the Food Additives Law and Regulation No. 177.1520. Blue pigment meets Regulations No. 175.300 and 177.2600.

UV Resistance:

No UV (ultraviolet) stabilizers are added to Tapco buckets because most elevator buckets are enclosed in casings. Tapco buckets should not be exposed to direct sunlight for extended periods of time.

Recommendations:

Polyethylene buckets are ideal for use with grains, feeds, fertilizers, seeds, food products, chemicals, sand, salt and most free flowing agricultural products handled in bucket elevators.

Limitations:

Polyethylene buckets should not be used with the following: (1) Materials over 200°F/93°C. (2) Sharp edged materials such as crushed glass or oyster shells. (3) Large dense materials such as gravel and ores over 3/8" diameter. (4) A few extremely abrasive and sluggish materials such as dried whey, some pellets and extruded feeds. (5) Some severe soybean and rice applications.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Nylon buckets can be ignited and will burn from improper welding and cutting.

Important:

When elevating certain materials that harden or set up with moisture, a Tapco steel digger bucket should replace every 10th polyethylene bucket. Contact Tapco for recommendations.